The growing menace of plastic waste pollution has driven a wave of innovation in sustainable recycling technologies. Among the most promising methods is Plastic Pyrolysis—a thermochemical process that transforms plastic waste into fuel. This article discusses the fundamental science, engineering design, system components, safety measures, input-output balance, and environmental implications of plastic-to-fuel technology using pyrolysis.

1. Basic Scientific Principles of Pyrolysis

Pyrolysis is governed by principles of thermodynamics and chemical kinetics. It is the thermal decomposition of organic material in the absence of oxygen, preventing combustion and promoting molecular breakdown.

Key principles involved include:

-

First Law of Thermodynamics: Energy conservation during heat input and chemical transformation.

-

Second Law of Thermodynamics: Entropy increases as complex polymers are broken into smaller molecules.

-

Chemical Kinetics: Reaction rates depend on temperature, catalyst, and molecular structure.

-

Le Chatelier’s Principle: Used in catalytic pyrolysis to steer reactions toward desirable outputs (e.g., fuel oil).

Common plastic types such as polyethylene (PE), polypropylene (PP), and polystyrene (PS) are thermally cracked into smaller hydrocarbon chains that can be condensed into oil.

2. Process Flow and Technology Implementation

The plastic-to-fuel process consists of the following stages:

-

Feedstock Sorting and Pre-treatment

-

Shredding to Uniform Particle Size

-

Feeding into the Pyrolysis Reactor

-

Thermal Decomposition (200–900°C) in Oxygen-Free Environment

-

Condensation of Hydrocarbon Vapors into Oil

-

Separation of Byproducts (Gas and Char)

-

Oil Refining for End-Use

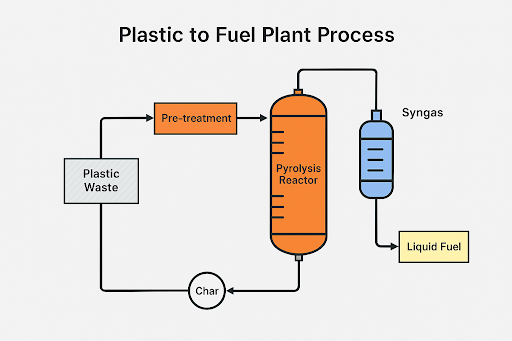

📌 PFD – Plastic to Fuel Process Flow Diagram

Process Flow Diagram (PFD) of the Plastic to Fuel Pyrolysis Plant

3. Key Components and Auxiliary Systems

-

Feed Hopper: Receives pretreated plastic waste.

-

Pyrolysis Reactor: Sealed chamber (SS316 or Inconel) that provides uniform heating.

-

Heating System: Electrical or gas-fired units for controlled temperature rise.

-

Catalyst Unit: Zeolite or silica-alumina to enhance cracking efficiency.

-

Condensers and Fractionation Units: Stainless steel heat exchangers for condensing vapors.

-

Gas Scrubbers and Flare Stack: For safe exhaust gas handling.

-

Char Collection System: For solid residue disposal or reuse.

-

PLC/SCADA Control Panel: For automation and safety interlock systems.

📌 Layout – Plastic to Fuel Plant Process Layout Diagram

4. Construction Materials and Standards

-

Reactor and Condenser: SS304, SS316, Inconel, or Hastelloy for high-temperature resistance.

-

Piping and Seals: PTFE or Viton-based materials.

-

Refractory Lining: Ceramic fiber or alumina bricks.

-

Safety Standards:

-

ASME Section VIII – Pressure vessel standards

-

API 650 – Tank fabrication standards

-

ISO 14001 – Environmental compliance

-

OSHA 1910 – Worker safety

-

5. Input Materials and Output Products

Acceptable Plastic Waste Feedstocks:

-

Polyethylene (PE)

-

Polypropylene (PP)

-

Polystyrene (PS)

Outputs:

-

Liquid Oil (TPO): Used as fuel for generators, engines, or refined into diesel.

-

Syngas: Recycled as heating fuel within the plant.

-

Char: Used in construction or pigment manufacturing.

Byproducts Applications:

-

Light oil: Fuel additive.

-

Heavy oil: Industrial heating.

-

Carbon black: Reinforcement filler.

-

Gas: Used for energy recovery within the process loop.

📌 Graph – Plastic to Fuel Output Comparison

Estimated Fuel Yield Based on Different Plastic Types

6. Environmental Impact and Mitigation

Risks:

-

VOC emissions

-

Chlorine release (if PVC is processed)

-

Explosion risk from syngas

-

Water or soil contamination

Mitigation Measures:

-

Oxygen sensors to ensure oxygen-free operation.

-

Scrubbers to capture dioxins and HCl.

-

Flare system for excess gas burning.

-

Regular PPE usage and personnel training.

-

Emergency shutdown systems (ESD).

Environmental Benefits:

-

Reduces landfill plastic burden.

-

Prevents ocean plastic accumulation.

-

Provides circular economy fuel.

-

Lowers dependence on fossil fuel refining.

7. International Standards and Compliance

The system should comply with:

-

EPA guidelines – Emission and fuel quality

-

ISO 45001 – Occupational safety

-

REACH / RoHS – Chemical content standards

-

Basel Convention – Waste material handling and export

8. Conclusion

Plastic pyrolysis presents a scalable and circular solution to the global plastic waste crisis. The conversion of non-recyclable plastics into usable fuel not only reduces environmental impact but also offers significant energy recovery. With proper engineering design, process control, and environmental safeguards, this technology can be safely integrated into modern waste management and renewable energy infrastructures.

📌 If

you are interested in seeing articles in other science & engineering, you can

find them 👉 here