Deaerator working principle, Types and Process Control

Deaerators is commonly employed in any chemical process industry or in Power Plants wherever boiler is utilized for steam production from boiler feed water. Deaerator solves the aim of removal of unwanted dissolved gases and dissolved oxygen from the boiler feed water before going in boilers. Most of the deaerators are designed in such how that the dissolved oxygen content within the outlet water is regarding7 ppb by WTC.

Principle of Dearators

Dearator commonly

works based on the subsequent principles.

Henry’s Law

According to Henry’s

low is in a liquid the gas solubility is directly proportional to the partial

pressure. thus if we tend to decrease the partial pressure of the dissolved gas

by adding steam in Deaerator, its solubility decreases and also the gas is faraway

from water.

Inverse Solubility of Water

When the temperature

of water is growing, the dissolved oxygen content within the water is

decreases. Thus the water temp. is growing by inserting steam in Deaerator, the

dissolved gas solubility is reduced and also the gases are withdrawal from

water.

Types of Deaerators

1. Tray types

Deaerator

Tray type deaerators

contain perforated trays within the top of the Deaeration section. The bottom portion

volume is high for used as storage for boiler feed water. Feed water to

deaerator enters into the perforated trays wherever the area and residence time

is growing to contact with steam. Then the water goes to the horizontal storage

section wherever steam is pass through sparger pipe to withdrawn the remaining traces

of dissolved gases and keep the stored water at its saturation temperature.

Tray Deaerator

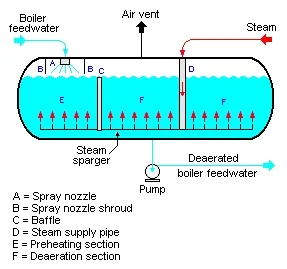

2. Spray type Deaerator

Spray Deaerator type

deaerator contains spray nozzle in feed water entry space. it’s then preheated

and deaerated and sent to storage section. In storage section also steam is

additional to stay the water at its saturation temperature.

Process control system in Deaerator

Deaerator operate in

very low pressure steam about 0.5 to 1.5 kg/cm2 with can produce in process

plant.The low steam sources could also be anyone of the following: Extraction

from back pressure turbines, Flash steam recovered from Boiler blow down or

letdown steam from high pressure steam header through pressure reducing valve. Steam

pressure within the deaerator should be maintained to facilitate the removal of

dissolved gases from water and also to produce adequate NPSH to boiler feed

pump. Deaerators are commonly put in at high elevation so as to produce enough

NPSH within the event of failure in steam pressure control conjointly. Pressure

safety valve is additionally fitted to avoid pressurization of deaerator

because of malfunctioning of pressure control valve.

Water Level control

Main sources of raw

water to deaerator are Treated water from water treatment plant and steam

condensate from the condensing type turbines. During the stable plant operation

the water balance is maintained and through any upset within the higher than

said sources water level fluctuates and control is important. High level and

low level alarms are provided. Low level might lead to starvation of feed water

in pump and High level leads to water entry into steam header. Thus overflow drain

is put in to drain the water if very high level is reached.

Deaerator Water Level control

Other benefits of Deaerator

Dearator acts as an

extra storage that provides reserve amount of boiler feed water throughout

upstream water supply failure for momentary periods commonly for about twenty

minutes.

In some of the Plants, Deaerator is additionally used for dosing oxygen scavenging chemicals like hydrazine or Hydroquinone.